About us

What we stand for

When it comes to building technology, casting technology and rolled products, we are flying the flag for progress. We are particularly committed to protecting the climate and using resources sustainably.

It's what counts in the end

Who we are

We are a world market leader operating on integrated global markets. When it comes to customer services for our three business units, Building Technology, Casting Technology and Rolled Products, the company headquarters and central production site in Olpe is supported by six German and nine foreign sales offices. As well as Germany, our sites are located in the Netherlands, Switzerland, Austria, Czech Republic, Denmark, the United Kingdom, the United States, China and Singapore.

Our core business is enhanced by our affiliated subsidiaries. In the Rolled Products business unit, this is Profiltech Stufenbandprofile GmbH in Keltern, which manufactures high-precision profiled strip. The design competency in Building Technology is complemented by Dendrit Haustechnik-Software GmbH in Dülmen.

Building Technology, Casting Technology and Rolled Products

Building Technology - valves and systems

Our building technology valves and systems to protect drinking water are synonymous with sustainability and ecology. Specialist wholesalers, designers, sanitary ware fitters and landlords of large public and private buildings put their trust in our branded valves all across Europe. The wide range of products is characterised by the successful symbiosis of robust, corrosion-resistant installation valves and modern building technology systems.

We offer a holistic concept for establishing and maintaining drinking water hygiene with our innovative solutions. Smart building services software components are also used for time and resource saving design.

Casting Technology - gunmetal parts - non-machined and machined

Our products place us among the world's leading suppliers. A major contributor to this is our vast experience in casting copper alloys. We are a specialist when it comes to particularly demanding and durable products. Expertise and experience are the basis of our exceptional quality. At the same time, we are our own single biggest customer because the renowned KEMPER branded valves for drinking water installations are produced at the foundry. The gunmetal used is not only corrosion-resistant, it also meets the strict requirements of the German Drinking Water Regulation - and is even lead-free, now and in the future.

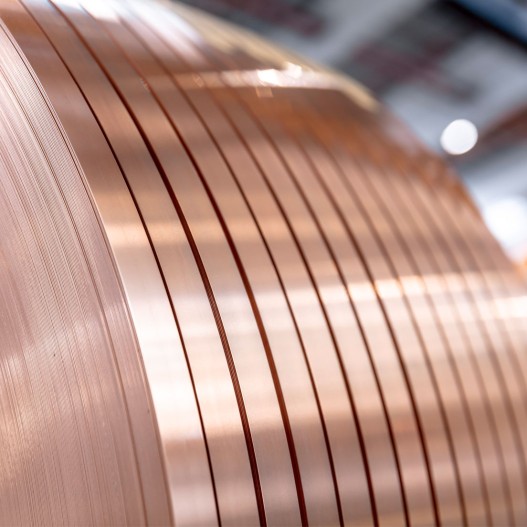

Rolled Products - copper and copper alloy strips

Our rolled products place us amongst the world leaders in the production of copper and alloy strips for the automotive and electronics industries. The high quality of our strips, which only a few companies worldwide are able to produce to this standard, is crucial when it comes to miniaturising electronic components.

The growing pace of electrification, networking, smart technology and sensor technology will also ensure continued progress in this area for the future. And we offer the right solutions for all these sectors thanks to our classic bronze and high-performance alloys. The company’s subsidiary, Profiltech Stufenbandprofile GmbH, finishes rolled strips by profiling them to customer specifications.

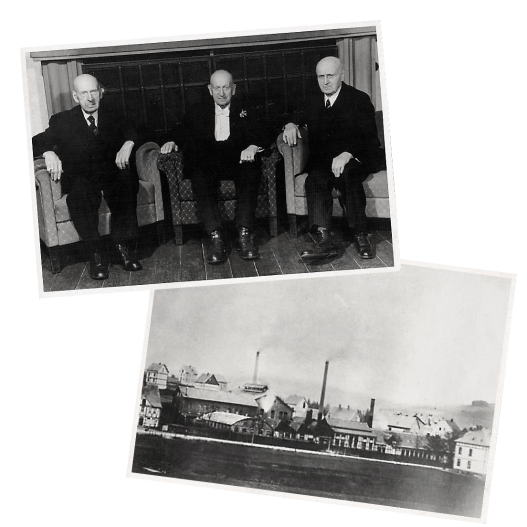

The second generation of brothers / foundry in Martinstrasse, 1906

Family business with over 160 years of history

KEMPER was established in 1864. Since then, the Kemper family has been running and managing the family company for several generations. Now we can look back on a moving and very successful history.

Our products may have changed over the years, but our philosophy remains the same: we are pioneers and want to constantly move forward.

Innovative solutions for the future

In our research and development work, we facilitate economic, environmental and social improvements, both in product development and process optimisation for Casting and Building Technology and in the improvement of production processes for Rolled Products.

The research and development departments take care of new and optimised products, processes and innovative materials. This is achieved together with many other specialist departments throughout the chain, from the initial idea to finished product.

We have partnerships with universities such as FH Münster, involving well-known experts in the fields of energy, building and the environment.

We believe quality is more than just a word

Quality is our promise to our customers and a key part of our corporate culture. Our processes are therefore continuously analysed and optimised because this is the only way that we at KEMPER can keep moving forward. We are proud of our tradition of manufacturing high quality products, which stretches back for over 150 years, and every day we set out to do justice to this aspiration.

Our skilled employees have years of experience in our branches of industry and receive regular training. In this way, we can ensure that our products and services meet the stringent requirements of our customers.

Expert knowledge - driving progress with KEMPER

We organise over 130 seminars every year at our own training centre and at external conference facilities for a wide professional audience including designers, installation companies, housing associations and operators of large buildings such as hospitals. This exchange with relevant target groups ensures that we can continue to develop innovative approaches to our own product development process.

Our most important capital are our employees.

Our success is due to a large extent to the reliability, know-how, creativity and high level of commitment of our employees. Only highly-qualified experts and managers can make KEMPER a manufacturer of high-tech products with lasting global market leadership. Therefore, we continuously invest in regular personalised training to improve the skills and knowledge of our employees.

Code of conduct

Our senior management is taking another step towards shouldering its local and global responsibility by introducing the code of conduct below, which has been systematically derived from our former corporate policies.

We also expect all of our business partners to fully make the following commitment set out below in the sense of a minimum requirement.