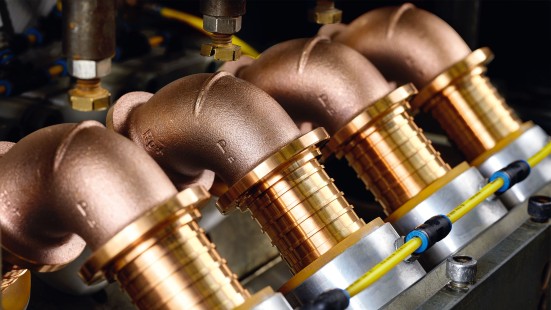

Gunmetal – multi-constituent bronze

KEMPER gunmetal – durable and versatile

Old bronze ship’s bells, artistic wine vessels and other finds from the Bronze Age (from circa 6000 B.C.) demonstrate the extraordinary durability of this material in impressive fashion, even when such witnesses of this innovative era have spent millennia in salty seawater. Gunmetal cast by KEMPER is a material very closely related to bronze (copper and tin) and is well suited to use in domestic water technology, particularly in drinking water and heating installations.

Gunmetal Rg5 - CC499K

Gunmetal is a valve and plumbing material standardised according in accordance with DIN 50930-6/DIN EN 1982, which is particularly suitable for plumbing thanks to its wide range of possible applications, for example as valve material for stop, safety and balancing valves, as fitting material for pipe system components and as construction material in water, filter and recycling engineering.

Components made of gunmetal

Thanks to the value of copper, along with the hygienic properties of tin, the easier workability of lead and the lower proportion of lead and zinc, gunmetal is used in many areas of life. The close relationship to bronze – gunmetal also being called multi-constituent bronze – is indicative of the considerable properties of this alloy. The corrosion-resistance of gunmetal is of particular importance, as gunmetal is corrosion-resistant against the types of corrosion that frequently occur in drinking water, namely dezincification and stress crack corrosion. This makes it useful in a wide range of applications.

Outstanding material properties

Thanks to these outstanding material properties, gunmetal can be used in situations involving drinking water and even aggressive seawater and process waters.

In this sense, products from petrochemistry, colours and lacquers and gases and liquefied gases are guided through components of this material. To this end, the material allows for use temperatures of –176°C to +225°C. This is because gunmetal exhibits almost no measurable brittleness even at such low temperatures. This is why it is primarily used as valve material in gas liquefaction. Even such critical, liquefied gas as oxygen, nitrogen, etc. are reliably guided, distributed and shut off at approximately –176°C by valves made of gunmetal.

Advantages

- Thanks to its higher Cu content, gunmetal is almost immune to dezincification

- Gunmetal can be used in all situations for all water qualities in accordance with the German Drinking Water Ordinance

- Gunmetal is applicable without restriction in accordance with all standards (50930-6, DIN 1988 etc.)

- Gunmetal is particularly corrosion-resistant

- Gunmetal is made from recycled material (old valves and components) without any loss of quality, thus protecting the environment and conserving resources

- This means gunmetal is a material you can rely on! Today and in the future!

New lead-free gunmetal “Rg+”

Less is sometimes more. As with our new lead-free alloy Rg+ This is a real milestone which further promotes health and safety and has less environmental impact. All this is achieved while maintaining its outstanding characteristics. As Rg+ can be cast similarly to Rg5 thanks to it having identical mechanical characteristics. Furthermore, Rg+ has comparable cutting characteristics. Its resistance to corrosion and dezincification is not just identical, as they can even sometimes outperform the original containing lead. The new alloy can be used as low as –176°C without the risk of embrittlement in cold conditions.

Rg+ is approved on the UBA positive list that is published nationally and certified in accordance with DIN SPEC 2701 with reference to the German Drinking Water Ordinance. We meet all the requirements of REACH and RoHS with this alloy.

Rg5 and Rg+ material comparison

- Rg+ can be cast almost identically like Rg5

- Rg+ has identical mechanical properties to Rg5

- Models can be taken on with slight adaptations

- Processing tools and tensioning devices can be taken on by existing articles

- Comparable cutting properties

- Corrosion- and dezincification-resistance identical and sometimes greater than Rg5

- Can be used up to –176°C (no embrittlement in cold conditions)

| Rg5 and Rg alloy comparison | |||

|---|---|---|---|

| Rg5 CuSn5Zn5Pb2 CC499K |

Rg+ CuSn4Zn2PS since 2018 |

||

| Alloy contents [% weight] | Copper | 84.0 - 88.0 | 90.0 - 96.0 |

| Tin | 4.0 - 6.0 | 3.0 - 5.0 | |

| Lead | 0.2 - 3.0 | <0.10 | |

| Nickel | 0.1 - 0.60 | <0.3 | |

| Sulphur | <0.04 | 0.20 - 0.6 | |

| Mechanical characteristics (sand casting) | Tensile strength [MPa] | 200 | 200 |

| 0.2% yield strength [MPa] | 90 | 90 | |

| Elongation at break [%] | 13 | 13 | |

| Hardness [HBW] | 60 | 60 | |